System for Initial Filling

With the initial filling, the filling of a wide variety of

liquids is automated. Liquids can be dispensed simultaneously at several dispensing points, whereby an individual filling quantity must be specified for each dispensing point.

Connected to your superordinate network computer, the article-specific dispensing quantities are imported, further details on the article type are imported into a parts list and are thus directly available for further processing.

In this way, you ensure that the right product and the right quantity are always dispensed in a traceable and logged manner.

|

Integration into your production process

Integration into your production database, e.g. by barcode, production number, filling quantity information. Automated forwarding of OK messages to the next station. |

|

|

Logging and storage of each process

Traceability and control. |

|

|

Calibrated delivery

The system guarantees calibrated filling of your workpiece. |

|

|

Article-specific delivery quantity

Different products on a production line often have individual filling quantities. The automatic import of the filling quantity data ensures this. |

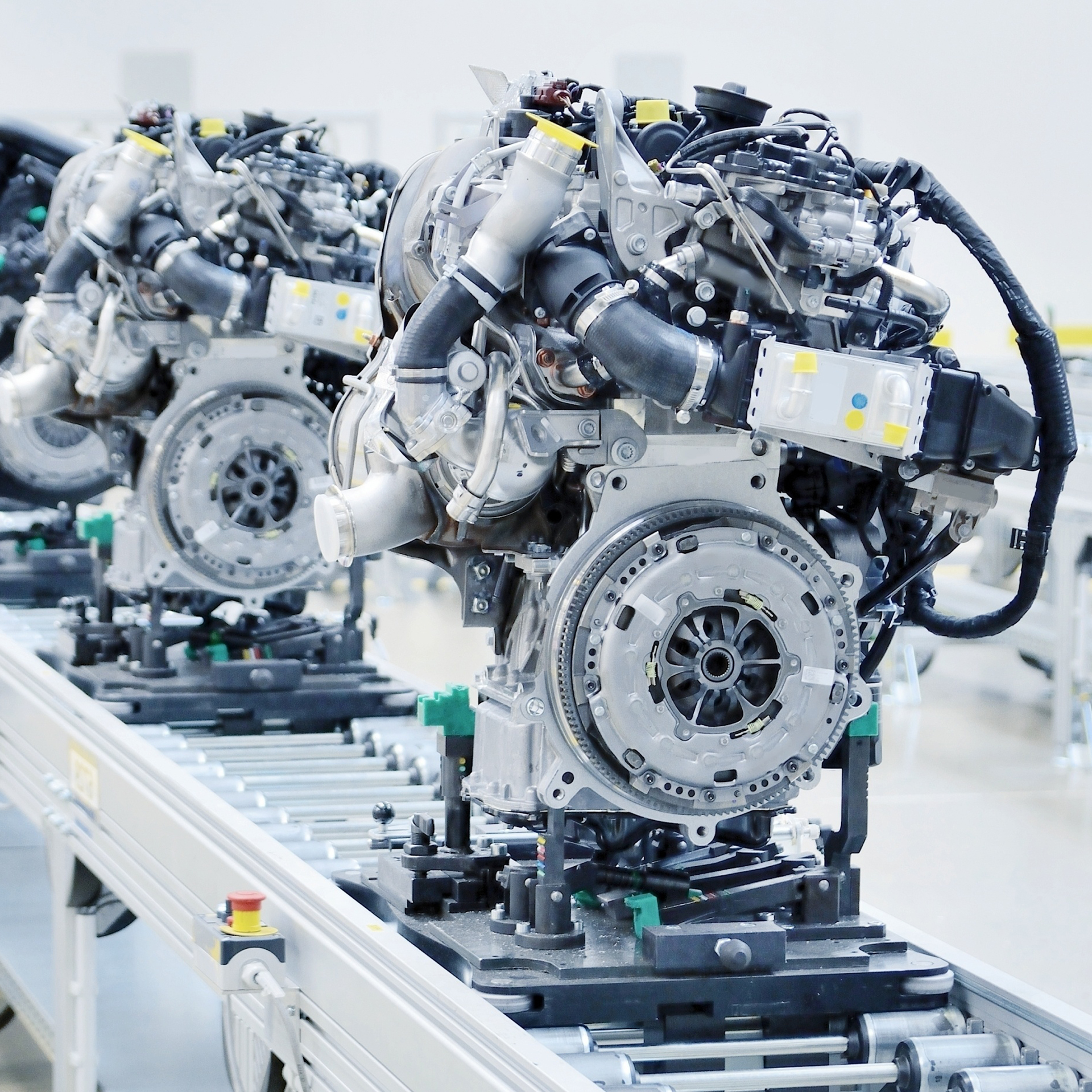

The filling system with the integrated PUZ 1000 is most frequently used in the automotive, agricultural machinery and aerospace industries for dispensing oils, lubricants or other liquids. Workpieces here can be, for example:

- Engines

- Gearboxes

- Vehicle axles

- Hydraulic systems

- Power units

- and much more

Any questions about the product?

We are gladly at your disposal!

Do you have questions, requests or a special task? Contact a personal contact person at i.Dohmann directly. Call us at our central telephone number – we will be happy to forward your call.

Phone: +49 (0) 5241 960600

E-Mail: service@dohmanngmbh.de